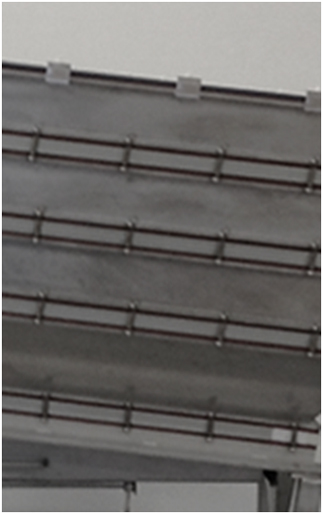

PUS SIEVING MACHINE

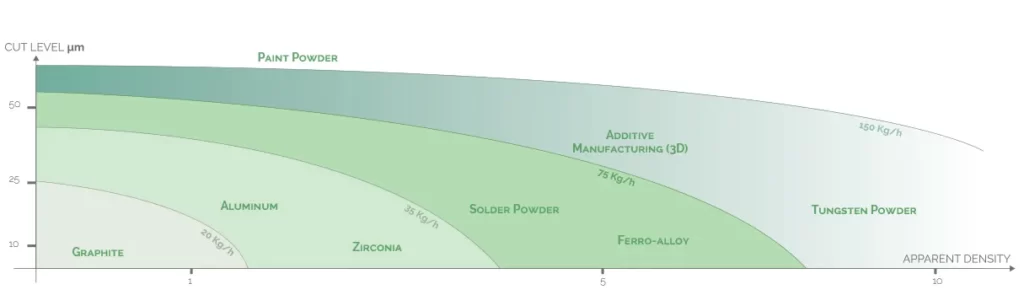

This revolutionary sieving principle (PUS International Patent) enables sieving without any high amplitude movement.

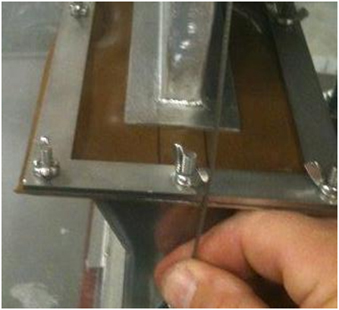

Each mesh screen is sequentially excited by ultrasonic vibrations. The powder is raised while the screen is unclogged. Then the powder falls one step below. The ultrasonic converter is positioned out of the machine, then protected from powder.

As the sieving is very efficient, the classification occurs mainly at the very beginning of the sieve, allowing a high number of levels in case of combined classification.

Our special preparation of screen allows classical mesh (20 to 210 µm- 625 to 70 US mesh) but is also able to screen down to 15 µm (1000 US mesh) and even lower.

STRENGTHS OF THE PUS PROCESS

- Compact Device- Fully airtight

- Able to sive at 15 µm and even lower

- Low noise level- No anchor to floor needed

- Several sieving levels are possible with no loss of efficiency

EXAMPLE OF USE

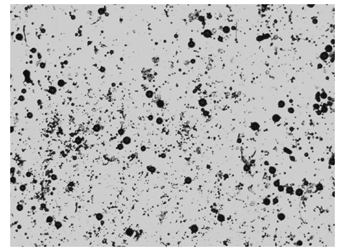

Graphite Powder

Target :

To sieve at 15 µm.

Challenge :

To allow a minimum flow for that light powder with such a low opening

Results :

We are able to offer this kind of classification to graphite powder for leading edge market. Our full sealing system allows an easy use for this powder where cleanliness is concerned.

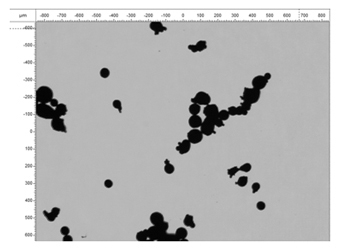

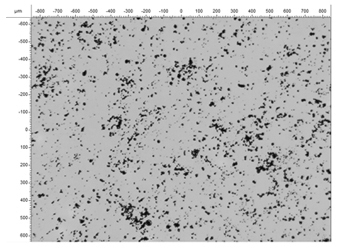

Aluminum Powder

Target :

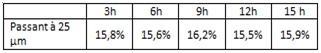

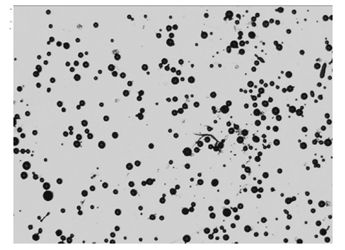

There are many types of aluminum powder. Some special alloys can be atomized with spherical shape and are used for very specific applications that will require very accurate cuts for example at 25 µm.

Challenge :

with that king of powder and this opening level, clogging is addressed.

Results :

We have a previce control of the ultrasonic vibrations that will allow very long time of use before cleaning clogging and wear free.

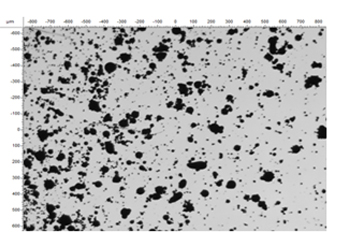

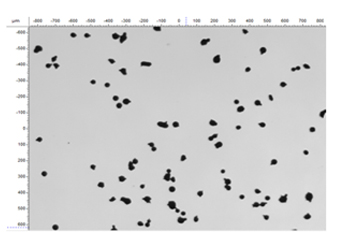

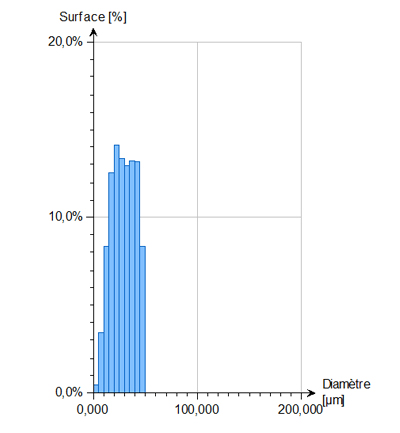

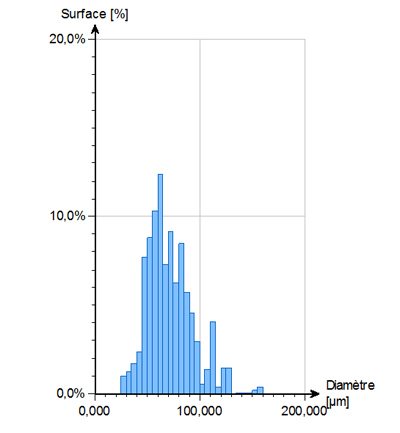

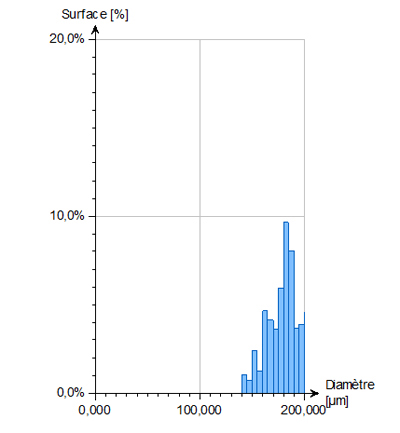

Example of results with aluminum powder at 50 kg/h flow

Zirconia Powder

Target :

To size the powder while adding a morphological sorting

Challenge :

With its laminar flow, we can adapt the allotted time on our sieving machine. Sorting at higher speed will enrich the undersize in smaller particles and regular shape ones. With a longer process time, or later on the mesh, will allow particles near the opening of the mesh or irregular shape ones to go through. This setting is easy to adapt and very consistent. We can add a morphological sorting to a high quality sizing.

Results :

High quality sorting at 34, 25 et 18 µm with flows between 30 to 50 kg/h. Removing fibers can be achieved!

Solder Powder

Target :

To be able to sieve atomized powder by sorting accurately following the standard types of powder (45 µm, 38 µm, 25 µm, 15 µm) with an optimal efficiency.

Challenge :

To avoid product transfer between several sieving machine as the majority of solder powder manufacturer performs now. (one sieving machine by step !)

Results :

Our unique sieving process allows a stacking of 5 meshes in a single step without sacrificing the sorting quality. Fine particles mainly go through the mesh in the upper part of it, so they can use the full area of the mesh close to their dimension. The machine needs only 1 sqm space on the floor while comparable classical solution will need more than 20, and will offer noise and vibration in addition!

Metallic powder for additive manufacturing (3D Printing)

Target :

To remove slags bigger than 63 µm and even 53 or 45 µm before re-using powder

Challenge :

A compact device that allows product losses at high flows in order to make the powder quickly available to reduce running stocks of powder.

Results :

For a 0.25 sqm mesh, outputs are around 80 kg/h for a perfect 63 µm cut.

Ferro-Alloy Metallic Powder

Target :

To remove particles over 45 µm and under 25 µm

Challenge :

Irregular shape, a lot of undersize

Results :

- a single step of sieving

- No clogging

- A 60kg/h flow for only a 0,5 m² mesh

Tungsten Carbide Powder : deposit for wear resistance

Target :

Calibrate powder under 40 µm

Challenge :

To avoid mesh clogging for these hard, dense and of randomly irregular shape

Results :

Mesh fully free of clogging after one week of work. No damages. Consistent size distribution all along the test.

Size distribution achieved

Paint Powder

Target :

For a perfect shape, Paint powders must be free of particles over 120 and even 100 µm.

Challenge :

To allow a 300 kg/h flow for these low density powders

Results :

Due to our innovative feeding system, powder uses all the sieving surface of the mesh, then achieving the flow target without lowering the yield. Big particles are withdrawn continuously. There is no need to open the sieving machine after each batch.

Target :

To size the powder while adding a morphological sorting.Challenge :

With its laminar flow, we can adapt the allotted time on our sieving machine. Sorting at higher speed will enrich the undersize in smaller particles and regular shape ones. With a longer process time, or later on the mesh, will allow particles near the opening of the mesh or irregular shape ones to go through. This setting is easy to adapt and very consistent. We can add a morphological sorting to a high quality sizing.

Results :

High quality sorting at 34, 25 et 18 µm with flows between 30 to 50 kg/h. Removing fibers can be achieved!

Target :

To sieve at 15 µm.

Challenge :

To allow a minimum flow for that light powder with such a low opening

Results :

We are able to offer this kind of classification to graphite powder for leading edge market. Our full sealing system allows an easy use for this powder where cleanliness is concerned.

Target :

To be able to sieve atomized powder by sorting accurately following the standard types of powder (45 µm, 38 µm, 25 µm, 15 µm) with an optimal efficiency.

Challenge :

To avoid product transfer between several sieving machine as the majority of solder powder manufacturer performs now. (one sieving machine by step !)

Results :

Our unique sieving process allows a stacking of 5 meshes in a single step without sacrificing the sorting quality. Fine particles mainly go through the mesh in the upper part of it, so they can use the full area of the mesh close to their dimension. The machine needs only 1 sqm space on the floor while comparable classical solution will need more than 20, and will offer noise and vibration in addition!

Target :

To remove slags bigger than 63 µm and even 53 or 45 µm before re-using powder

Challenge :

A compact device that allows product losses at high flows in order to make the powder quickly available to reduce running stocks of powder.

Results :

For a 0.25 sqm mesh, outputs are around 80 kg/h for a perfect 63 µm cut.

Target :

To remove particles over 45 µm and under 25 µm

Challenge :

Irregular shape, a lot of undersize

Results :

- a single step of sieving

- No clogging

- A 60kg/h flow for only a 0,5 m² mesh

Target :

For a perfect shape, Paint powders must be free of particles over 120 and even 100 µm.

Challenge :

To allow a 300 kg/h flow for these low density powders.

Results :

Due to our innovative feeding system, powder uses all the sieving surface of the mesh, then achieving the flow target without lowering the yield. Big particles are withdrawn continuously. There is no need to open the sieving machine after each batch.

Target :

Calibrate powder under 40 µm

Challenge :

To avoid mesh clogging for these hard, dense and of randomly irregular shape

Results :

Mesh fully free of clogging after one week of work. No damages. Consistent size distribution all along the test.

Size distribution achieved

Target :

There are many types of aluminum powder. Some special alloys can be atomized with spherical shape and are used vor very specific applications that will require very accurate cuts for example at 25 µm.,

Challenge :

with that king of powder and this opening level, clogging is addressed.

Results :

We have a precise control of the ultrasonic vibrations that will allow very long time of use before cleaning clogging and wear free.

Example of results with aluminium powder at 50 kg/h flow